Fiber-reinforced polymer (FRP) pedestrian bridges are becoming a competitive alternative to conventional concrete and steel pedestrian bridges in spans ranging from 5 to 30 m. FRP materials are light-weight, high-performance, and durable materials which have a proven track record in a range of corrosive environments. Multiple life-cycle costs analyses have shown FRP bridge construction to be a competitive economic option when considering the associated costs to design, construction and maintenance operations. One way of achieving the cost competitiveness is by producing standardized systems to create a catalogue of pre-engineered and versatile solutions for small and medium span pedestrian bridges.

Pedelta has led a research project to develop SUPERBAM, a new cost-effective and standardized pedestrian bridge. SUPERBAM provides the benefits of being high-strength, light-weight with the excellent durability of FRP materials. The emphasis on this Research Project has been to develop an efficient, competitive and aesthetically appealing structure system for small and medium span pedestrian bridges. The research has focused on conceptual studies and numerical models to validate and optimize the concepts. The constructed prototype has been tested in a research lab.

A detailed structural analysis and optimization of various cross-sections and laminate solutions have been carried out by using the Finite Element Method (FEM) under both static and dynamic loads to achieve the most cost-effective design. A specialized finite element analysis software has been developed with features that include pre-defined laminates database, automatic geometric construction and standard load cases definition. By using these tools, it is possible to make highly reusable moulds for laminates which in turn will lower the overall cost of FRP bridges.

IntroductionThe development and improvement of sustainable mobility around the world is urging the construction of pedestrian bridges in urban, rural, and remote areas. Meanwhile, developed countries around the world are coping with aging of transportation infrastructure. A significant number of bridges require periodic maintenance, even after major repairing or replacement to safely fulfill their functions. Construction of public infrastructure has a significant impact on sustainability, and the use of advanced materials such as FRP and stainless steel (SS) contributes to their sustainable development.

The goal of this research project is to use high-strength, light-weight, and reusable materials that require minimum maintenance and accelerate the construction. Most of the existing FRP pedestrian bridges are trusses made with pultruded standard profiles. There are technical limits on the use of these systems, mainly because of the fabrication process and the poor aesthetics. In addition, the connections are typically bolted and their design is one of the most critical challenges.

Adhesive connections can also be used in combination with bolts. There is a need in the bridge industry for the development of new structural concepts using FRP or hybrid structures.

The SUPERBAM Research Project was initiated accordingly, and it has developed specific geometries and aesthetically pleasing structural concepts to take full benefit of advanced materials (i.e. high-strength, light-weight, durable, and sustainable) by using modular systems.

Objective of the research

The objectives of the SUPERBAM Research Project include the following tasks:

- Develop a catalog of standard pedestrian bridges made with advanced materials to cover small and medium spans (spans from 10 to 30 m). The structures will be assembled using light-weight modular members/profiles. Focus will be on the connections between members, which should be reliable and easy to build.

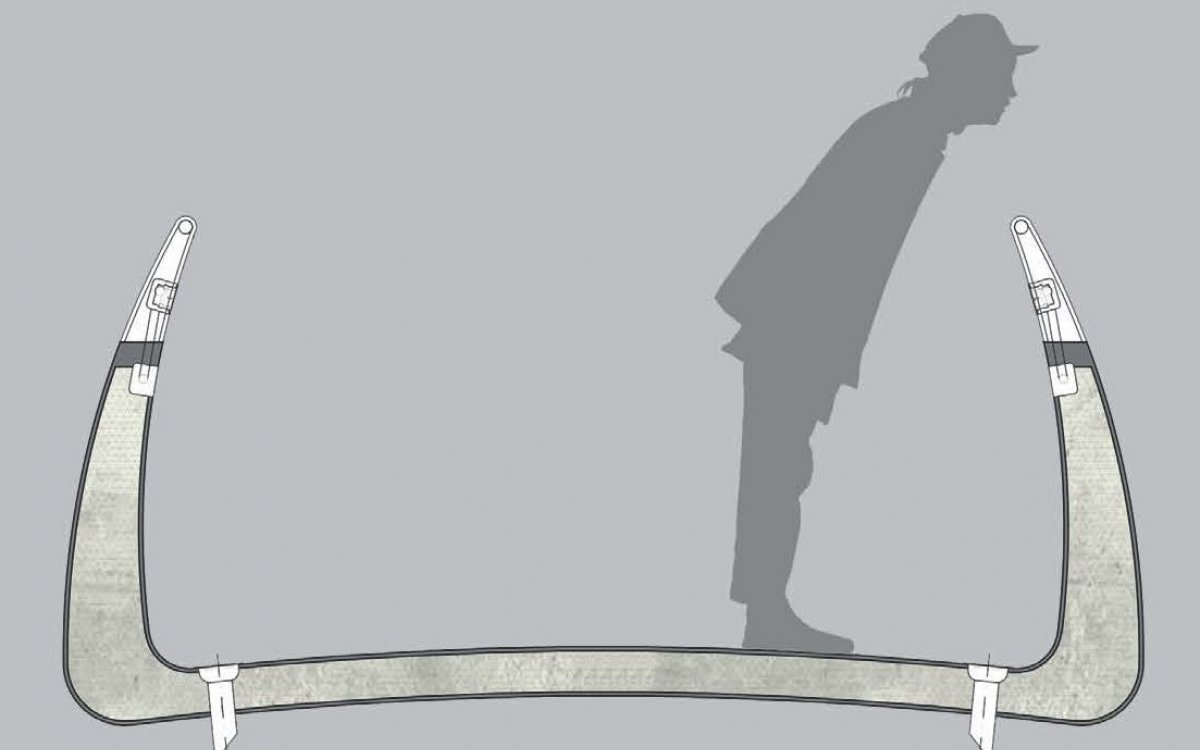

- Prepare a standardized new concept by using railings as a part of the structure to optimize the use of materials.

- Minimize the amount of connections in the structural system by using modular construction techniques.

- Enhance the bridge aesthetics and provide room for customized details such as integrated lighting, handrailing and colours.

- Develop specific methods for the design and sizing of the FRP structure.

- Develop specific structural software for the detailed design, including tools for the design of connections.

Technological steps and how they have been addressed

The purpose is to develop specific FRP or hybrid structural concepts for pedestrian bridges instead of repeating the same solutions already being used for concrete and/or steel structures. This conceptual design includes the design of a modular construction structural system, the analysis of the dynamic behavior of ultra-light structures to mitigate vibration, and the design of connections and methods of assembly.

A feasibility study of deployable foldable structures has been conducted to assess the possibility of obtaining a structure with the ability to change its geometry from a compact configuration to a functional shape. A deployable structure requires active elements during installation. The new concepts are validated by using a specific numerical software, or adapting advanced numerical codes used in other industries (e.g. aerospace and naval industry).

An analysis of the manufacturing process was also conducted to select:

- the most suitable materials (e.g. GFRP, CFRP, Stainless steel, hybrid structures),

- the fabrication process (e.g. pultrusion, vacuum infusion, hand layout, etc.), and iii) the structural shapes.

Fabrication technique

The traditional techniques that are used in the fabrication of the FRP components include:

MoldThe main structure has a U-shaped form and profiles will be constructed using separate molds. The molds should allow for the creation of various identical sections with minimal efforts. They must be cost-effective and reusable, and thus continued experimentation is being done. Molds are typically constructed by using a model.

To start, a prototype of the section is prepared and refined to eliminate imperfections. Successive layers of fabrics pre-impregnated with liquid resin are then placed to create an inverted self-supporting structure (i.e. the mold).

Both single-use molds and permanent molds are possible. Molds can also be divided into male and female molds. A male mold is used to form the interior of the structure, and a female mold is used to form the exterior of the structure.

External laminateThe mold surface is stabilized at a high temperature and undergoes a vacuum integrity test. A release agent is applied on the stabilized mold surface. This is then typically followed by a thick layer of gelcoat, which is intended to provide a uniform finish with the desired color. A liquid resin is then applied and the first layer of reinforcing fabric is placed on top of it. Rollers are used to apply pressure over the fibers to infuse and deaerate the layer. These steps are repeated by applying layers of fabric and resin until the desired thickness is reached while ensuring that layers fit perfectly to the complex shape of the mold. Vinylester is used as a mat and is placed between consecutive thin fabric layers to absorb the resin and to achieve the thickness. An evolution in the structural design and resin matrices has allowed for a reduction in the use of the mat and a substantial increase in direct fiber proportion in the laminate. This reduces the number of layers necessary to obtain the design strength.

Vacuum techniqueThe incorporation of vacuum techniques in traditional contact lamination leads to important advances in physical and mechanical properties of composite materials. A soft closed container shrinks and eventually collapses if external pressure increases. The same effect occurs if the internal pressure decreases. By enclosing the laminate in a sufficiently sturdy bag and removing the air within, a uniform pressure of approximately 1 atmosphere (101.325 kPa) can be obtained at any point even if the form is complex in shape. The results obtained by vacuum lamination present significant advantages over traditional contact lamination. Benefits from this technique include reduction in thickness, air content and final weight. In addition, homogenous and uniform quality along with fewer imperfections is being achieved.

Sandwich infusionThe most basic and common process of all infusion techniques consists of first placing layers of fibers – the core – and other inserts over the outer surface of the mold without using resin. This can be done slowly to ensure a clean shape, which is an important factor for the final quality of the piece and the entire project. Once this first step is completed, the vacuum bag and other items specific for the infusion are placed over the group. When the assembly is sealed with the help of the vacuum, the first compaction is carried out to stabilize the piece, to increase fiber content per volume, and to reduce voids. After reaching the desired level of compression, inlets are opened to saturate the piece with liquid resin while all the air inside is expelled using vacuum tubes.

Assembly and finishingThe various pieces that comprise the pedestrian bridge are put together with mechanical connectors and structural adhesives. The final assembly will require final finishing, painting and polishing, until the desired finish is achieved.